Hiplastics vision has always been to create a more eco-friendly retailing future. Our use of raw materials is also more environmentally friendly. From the previous use of PVC to complete our extrusion process, to the current R & D team’s use of HIPS ,PETG and other environmentally friendly materials, all reflect our great progress in the field of environmental protection.

HIPS, short for High Impact Polystyrene, is a versatile and popular material used in various industries. It is a type of plastic that is lightweight, durable, and has excellent impact resistance, making it the ideal choice for a wide range of applications. It have excellent thermal stability and shear stability, and can accept a large amount of recycled materials without reducing product performance. The amount of recycled material used in the thermoforming process can be as high as 60%. At the same time, HIPS this material is also easier to color, you can adjust the color according to your needs. The big advantage of hips is their low price. It is therefore cost-effective and can replace materials such as abs plastics without affecting output. In this way, producers who want to produce high-quality products at low prices have an advantage.

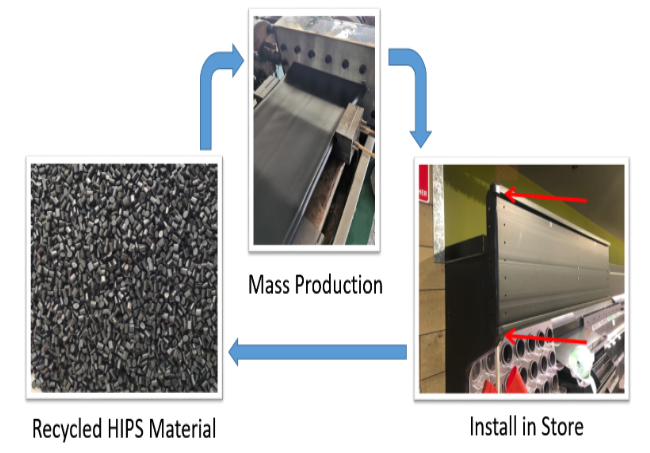

We will purchase a large number of HIPS recyclable raw materials, unified screening and testing of raw materials, and then put into production after ensuring that raw materials are available. As shown in the following figure, it is the use of our HIPS raw materials. These recyclable raw materials can still show a good appearance after processing in our production line, with smooth appearance and uniform color.

We believe that this will become your new choice, any interest please feel free to contact us.