During the period from November 12 to November 19, the Italian investor visited our production factory and gave suggestions for optimization in different aspects.

From November 13 to November 14, they visited our production line and put forward specific opinions on the standardization of our ESL lable holder production process and the clarity of production objectives. In the next production, we can more clearly grasp several key time nodes, prevent basic errors in the production process, and ensure that every customer’s order can be the most efficient completion of production.

In the next few days, they had in-depth communication with our ESL lable holder raw material suppliers to control product quality more strictly from the source. At the same time, they also give optimization suggestions for our R&D mold and quality inspection. This provides us with a lot of new ideas for research and development, from drawing design to mold changes, to ensure greater production stability. At the same time, they also propose new requirements for our OEE form, so that we can find the key to increase production capacity in the next production process.

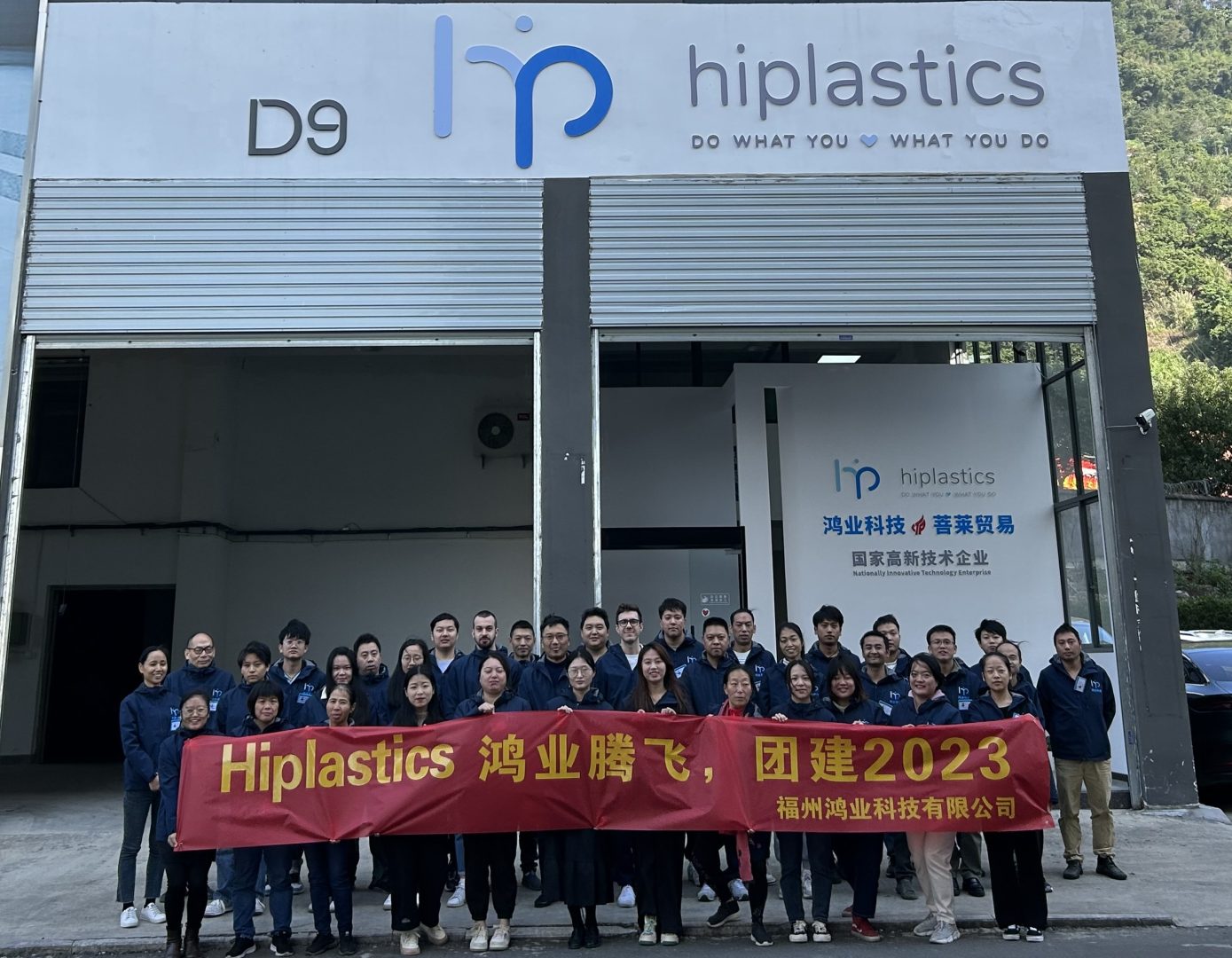

In the last two days, we organized a group building activity, which narrowed the distance between us. I believe that we can have a better understanding in the future work and create more achievements.